Aluminum Heat Exchanger Manufacturers in Coimbatore are an alternative option and Light in weight; Aluminium heat exchangers also transfer the high heat but require special inhibitors to maintaining the system. If special inhibitors are not used, then it can result in a high risk of damage to the boiler. The pH treatment is critical to the longevity of the heat exchanger.

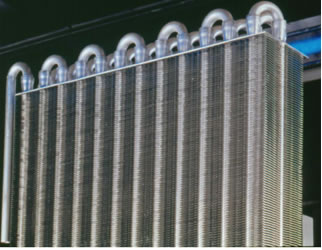

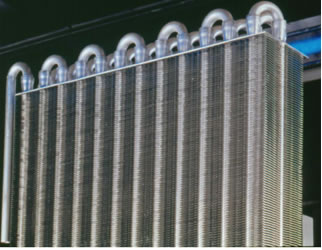

Owing the years of experience we bring forth an enticing range of Aluminium Heat Exchangers which is manufactured using quality aluminum that is procured from reliable vendors. We manufacture and supply a high-quality range of Aluminum Heat Exchangers from Coimbatore Tamilnadu. Our product has found its vast application in various industries and is appreciable for its efficient performance. These heat exchangers are manufactured by our skilled professionals and are known for their dimensional accuracy.

Aluminium heat exchangers are devices that are used to transfer heat between two fluids, while keeping them physically separated. They are made of aluminium, which is a lightweight and highly conductive metal known for its excellent heat transfer properties. Aluminium heat exchangers are widely used in various applications, including automotive, aerospace, HVAC (Heating, Ventilation, and Air Conditioning), refrigeration, and industrial processes.

Aluminium heat exchangers offer several advantages, including high thermal efficiency, lightweight construction, corrosion resistance, and good formability for various shapes and sizes. They are also cost-effective compared to other materials, such as copper or stainless steel, making them a popular choice for many heat transfer applications. Additionally, aluminium is environmentally friendly as it is 100% recyclable, which makes aluminium heat exchangers a sustainable option.

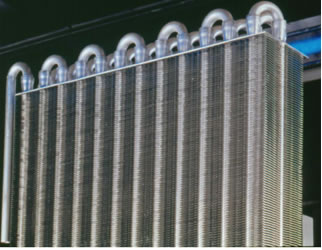

However, there are also some limitations to aluminium heat exchangers. They may not be suitable for applications that involve high pressures or high temperatures, as aluminium has lower strength compared to some other materials. Care must also be taken to prevent galvanic corrosion when aluminium is in contact with other metals in certain environments.

Overall, aluminium heat exchangers are widely used and offer numerous benefits in terms of thermal performance, weight savings, and cost-effectiveness in a variety of applications where heat transfer is critical.