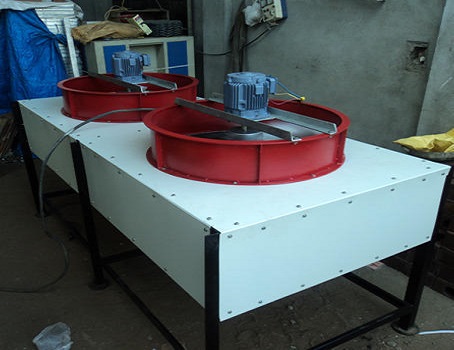

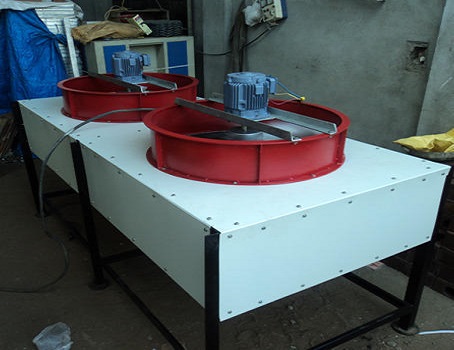

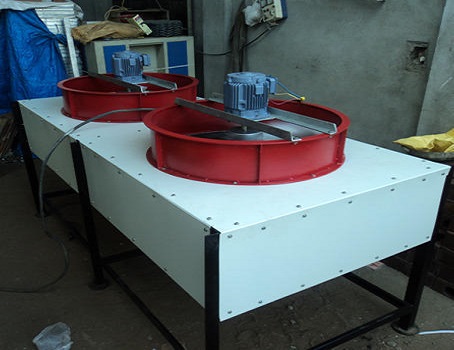

Gireesh Heat Exchanger – Cooling Towers is one of the prominent Air-cooled Heat Exchanger suppliers in Coimbatore, Tamilnadu. Air-cooled heat Exchangers are the same In the Functions of Finned Tube Heat Exchanger. This type of warmth Exchangers are Specially utilized in great quantity cooling Requirements. We are the main Suppliers of Air-cooled device for Oil Refineries and Process Fluid Cooling. The essential principles are the same but these are specialized items and are normally configured as an A-frame or "Roof Type". These condensers could even be very large—the condensers for a 4000 MW power station in South Africa have over 2300 tube bundles, 288 fans each 9.1 m in diameter, and a complete plot area 500 m × 70 m.

The design of an ACHE is more complex than a Shell and Tube device, as there are more components and variables.

Air-cooled heat exchangers (ACHEs), also known as air-cooled condensers or air-cooled radiators, are heat exchangers that use ambient air as the cooling medium to remove heat from a process or system without the need for an external water source. They are widely used in various applications where water is scarce, expensive, or not desirable for cooling, such as in power plants, refineries, petrochemical plants, HVAC systems, and industrial processes.

Air-cooled heat exchangers offer several advantages. One of the main advantages is their independence from a water source, which eliminates the need for water treatment, pumping, and associated infrastructure, making them more cost-effective and environmentally friendly in water-scarce regions. They are also relatively simple in design and require less maintenance compared to water-cooled heat exchangers, as there are no water-related issues such as fouling, scaling, or corrosion.

Air-cooled heat exchangers are also more flexible in terms of installation, as they can be located outdoors or indoors, and their modular design allows for easy scalability and customization to meet specific heat transfer requirements. They can be used for both high-temperature and low-temperature applications, and they can handle a wide range of fluids, including gases, liquids, and multiphase flows.

However, air-cooled heat exchangers also have some limitations. They typically have lower heat transfer efficiency compared to water-cooled heat exchangers, as the heat transfer coefficient of air is lower than that of water. This may result in larger sizes and footprints compared to water-cooled heat exchangers for the same heat duty. Additionally, air-cooled heat exchangers may be affected by ambient conditions, such as temperature, humidity, and wind, which can impact their performance.

In summary, air-cooled heat exchangers are widely used in applications where water is not readily available or not desirable for cooling. They offer advantages in terms of cost-effectiveness, environmental sustainability, and flexibility in installation, but may have lower heat transfer efficiency compared to water-cooled heat exchangers. Proper design, operation, and maintenance considerations are important to ensure optimal performance of air-cooled heat exchangers in a given application.